Email: Tel:

Home Products edge banding machine edge banding machine

Intelligent control

Standard PLC microcomputer control, using the principle of time control, greatly increases stability and safety.

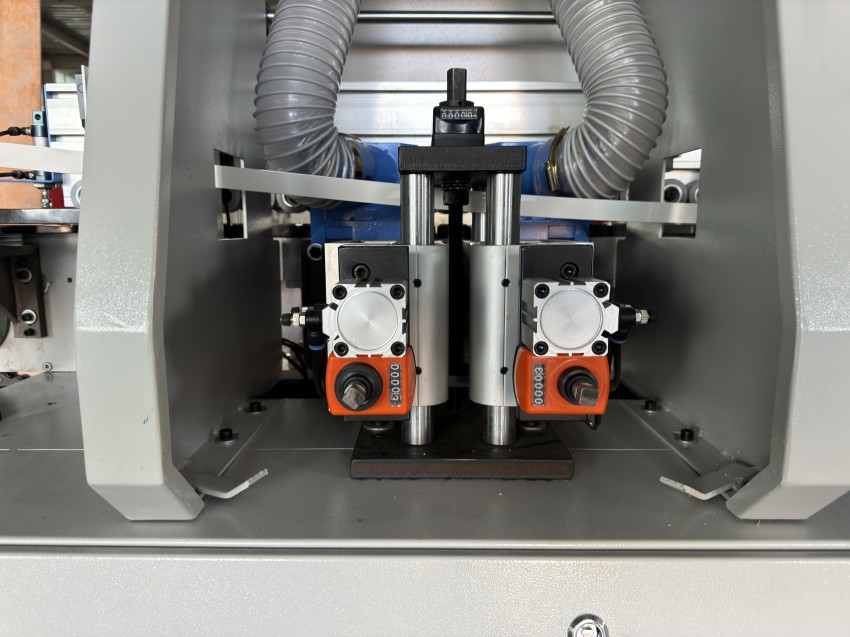

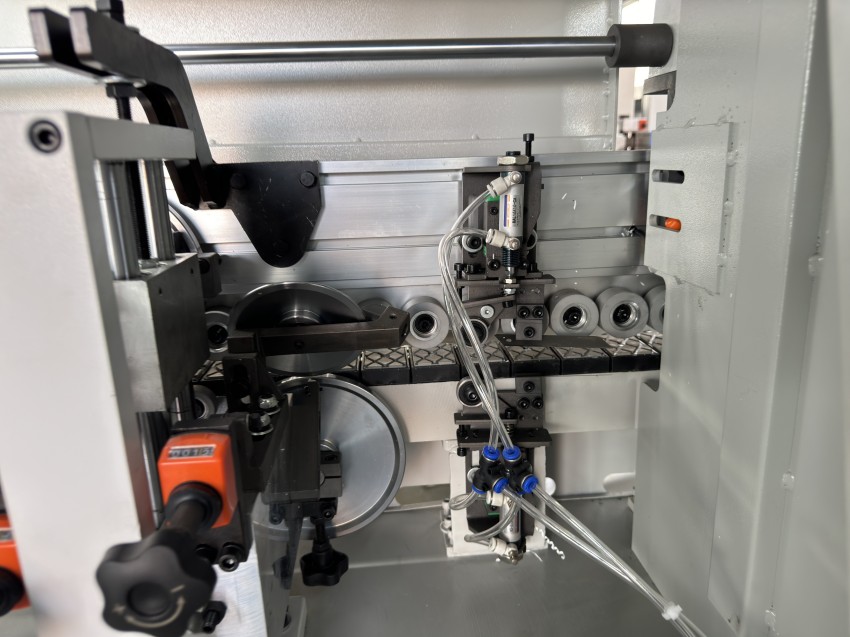

Pre-milling

Double milling cutters are used to trim the edges of the board with grain marks, burrs, or non perpendicular cutting to achieve better edge sealing effect.

Glue tank

The glue coating device heats hot melt adhesive through a glue pot and uses a spiral structure to evenly apply glue, ensuring a strong adhesive force.

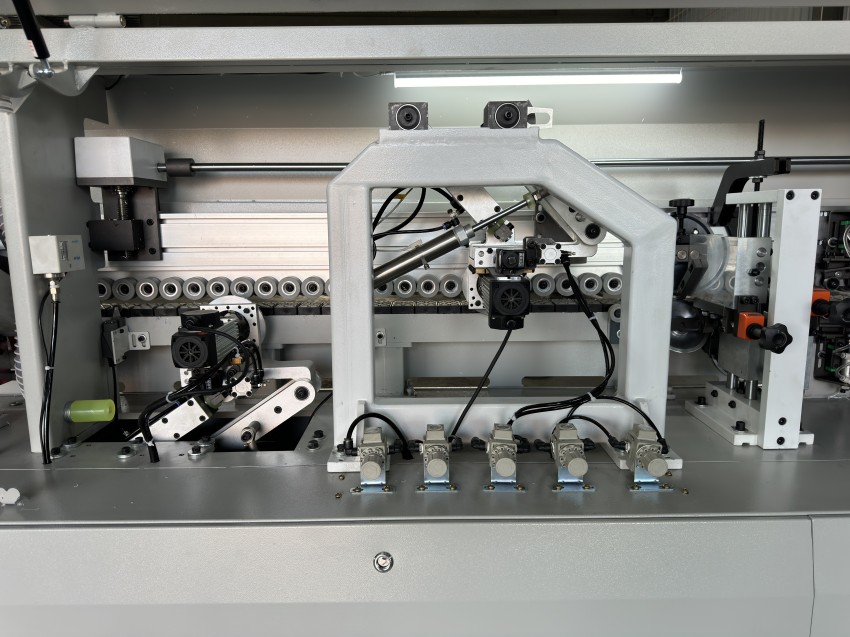

End cutting

Qitou adopts a single guide rail to cut the edges of the board at both ends.

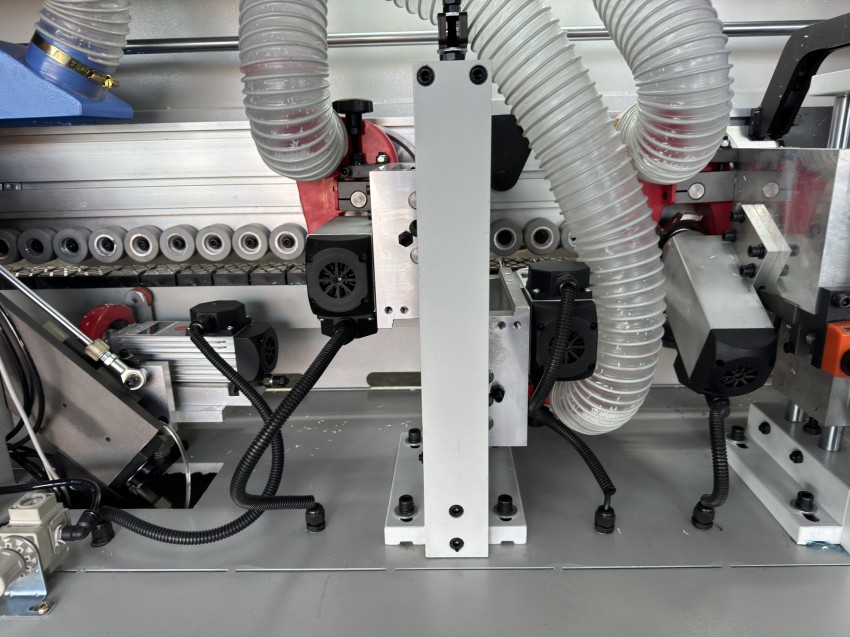

Rough trimming

In order to prevent the breakage of veneer during sealing, it can also be used as the first leveling process for PVC and acrylic edge sealing, reducing the cutting force and wear of precision cutting tools.

Fine trimming

High speed oblique cutting motor, adjustable operation is more convenient, and the alloy disc ensures smooth and even trimming.

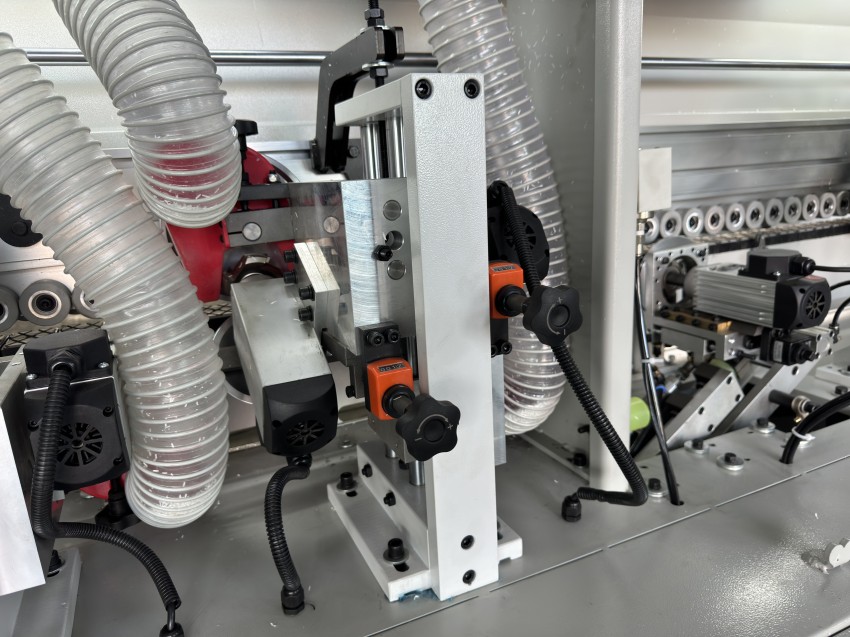

Comer round

High speed oblique cutting motor, adjustable operation is more convenient, and the alloy disc ensures smooth and even trimming.

Scraping

Used to eliminate ripple marks caused by non-linear cutting processes during edge trimming, making the upper and lower parts of the edge material smoother and neater.

Flat scraping

After scraping the edges of the board, it can be gently scraped and trimmed again for better results.

Buffing

Polishing makes the edge sealing section smoother and more effective.